Catalog

| № | Name of parameters | Result |

|---|---|---|

| 1 | Beryllium oxide content, % | 99,82 |

| 2 | Total oxide content(Ni, Fe, Ca, Si, Mg, Al, Zn, Cr), % | 0,18 |

| 3 | Density, g / cm3 | 2,92 |

| 4 | Grain Size, micron | 50 - 100 |

| 5 | Thermal Conductivity, W/m·K | 300,2 |

| 6 | Volume Resistivity, Ω-cm | 4,3x1016 |

| 7 | Dielectric permittivity, 1 MHz | 7,261 |

| 8 | Dielectric losses tanget, 3 GHz | 2,087x10-4 |

| 9 | Breakdown voltage, kV/mm | 45,9 |

| 10 | Static bending strength, kgf / cm2 | 2092 |

Note: Standards for indicators according to paragraphs 5-8 at a temperature of 15-30 о С

Black ceramicunique development

For high-power TWL devices (traveling wave lamps) it is necessary to create microwave absorbing materials of increased thermal conductivity. For this purpose it is necessary to use high thermal conductivity composite ceramics, one of the components of which must be well pass microwave radiation, and the other absorb. One such promising material from the KAZ CERAMICS LLP product range is ceramics containing BeO and TiO2 powder. The volumetric microwave energy absorbers produced are structurally stable, have uniform electrophysical properties, and maintain stable properties over a wide temperature range. As a result of sintering in a reducing hydrogen environment of oxide-beryllium ceramics with the addition of TiO2 micropowders, its density and electrical conductivity increase, the ability to absorb electromagnetic radiation in a wide frequency range appears. The most effective material is the composition in which the mass content of TiO2 in the BeO ceramic is 30 wt.%, that is, BeO + 30 % TiO2, (hereafter % by mass). Such ceramics are called BT-30. The attenuation factor of microwave radiation passing through the ( ВеО + TiO2)-ceramics in the frequency range of 8.5 - 12 GHz is 19 - 20 dB. The increase in the carbon admixture in the ceramics is accompanied by an increase in the electrical conductivity of ( ВеО + TiO2)-ceramics.

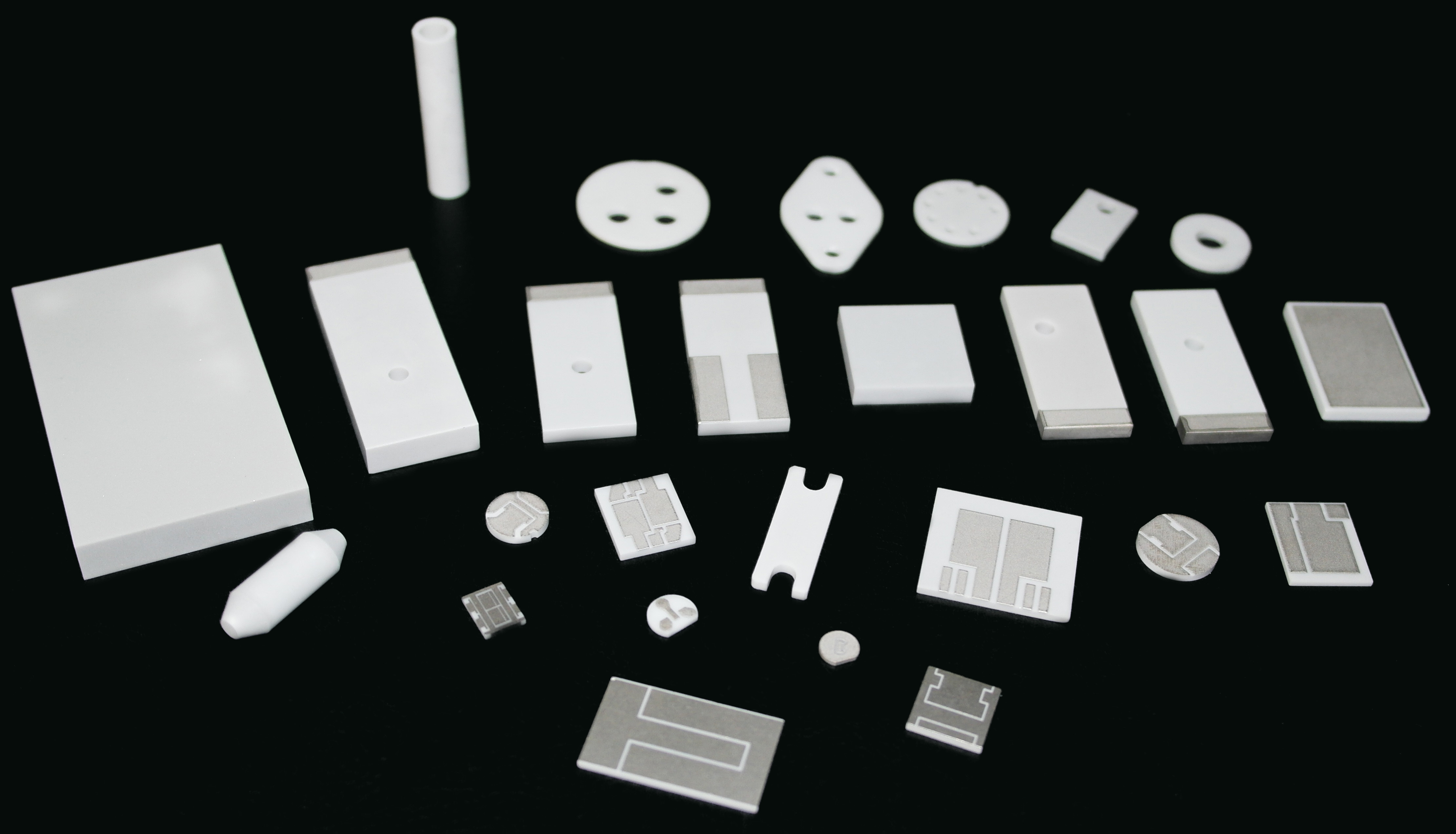

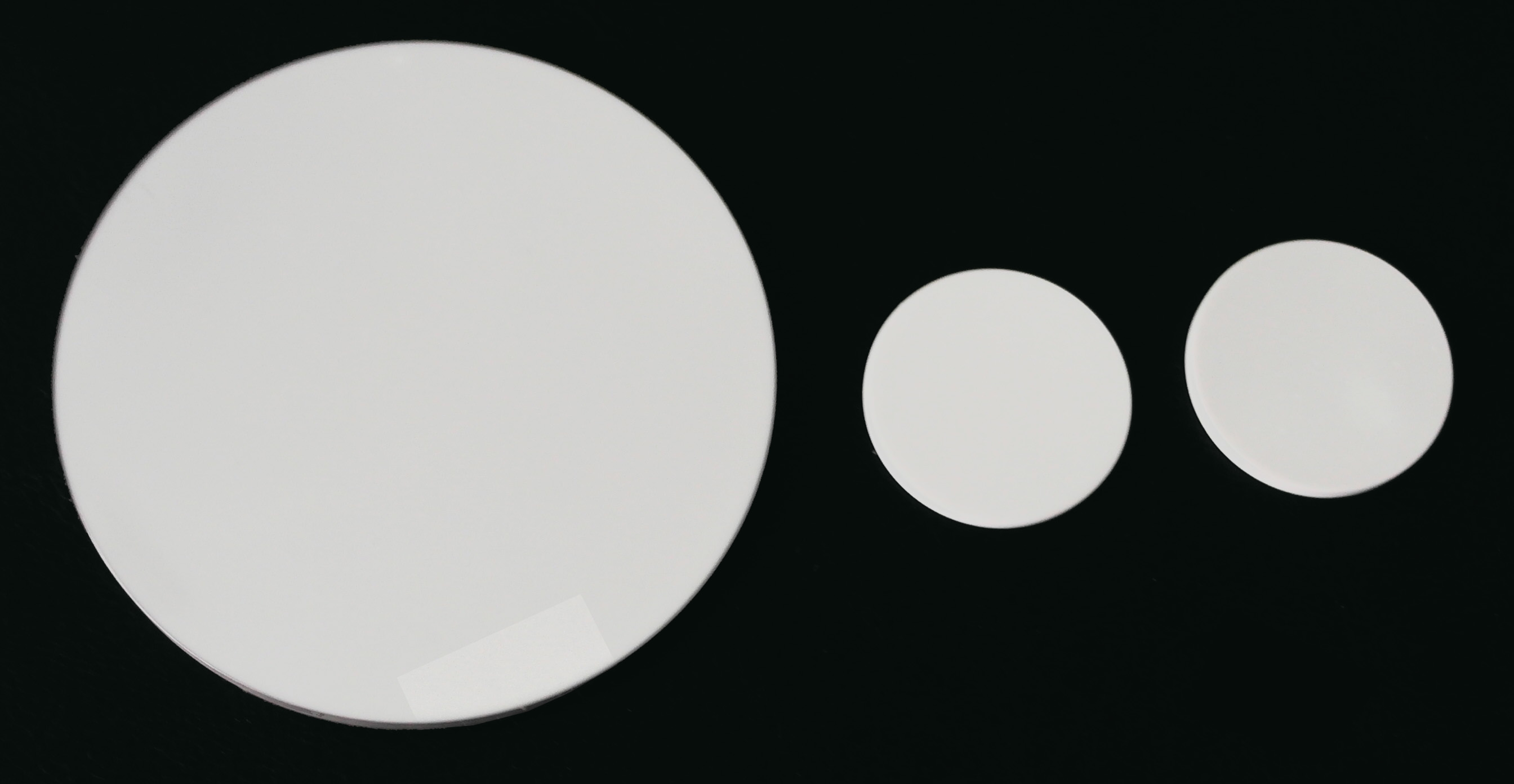

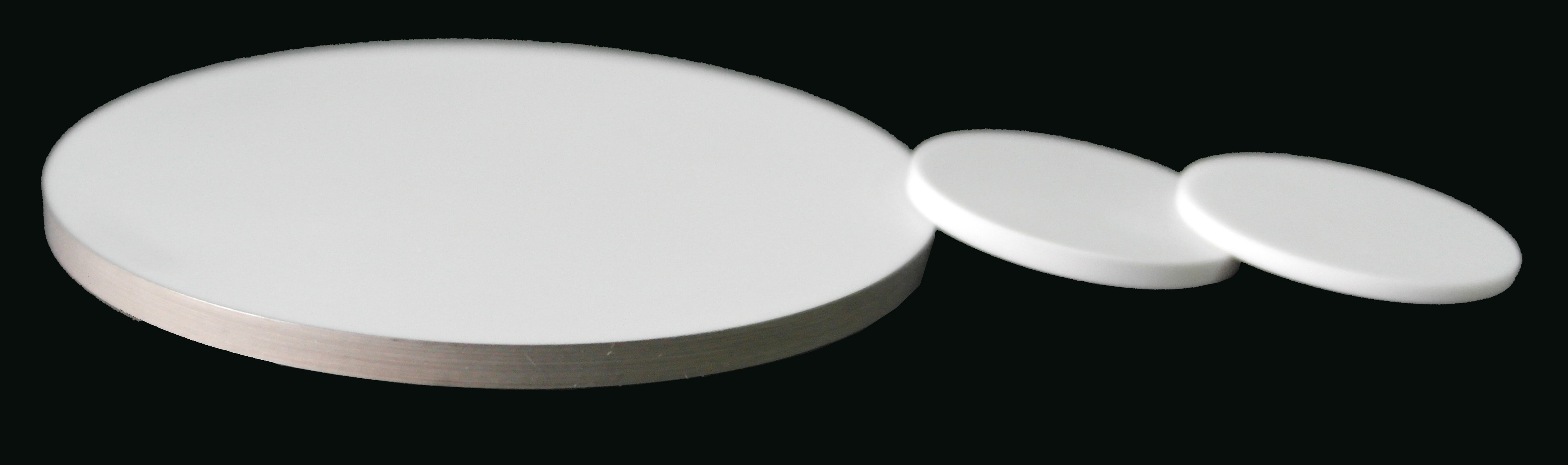

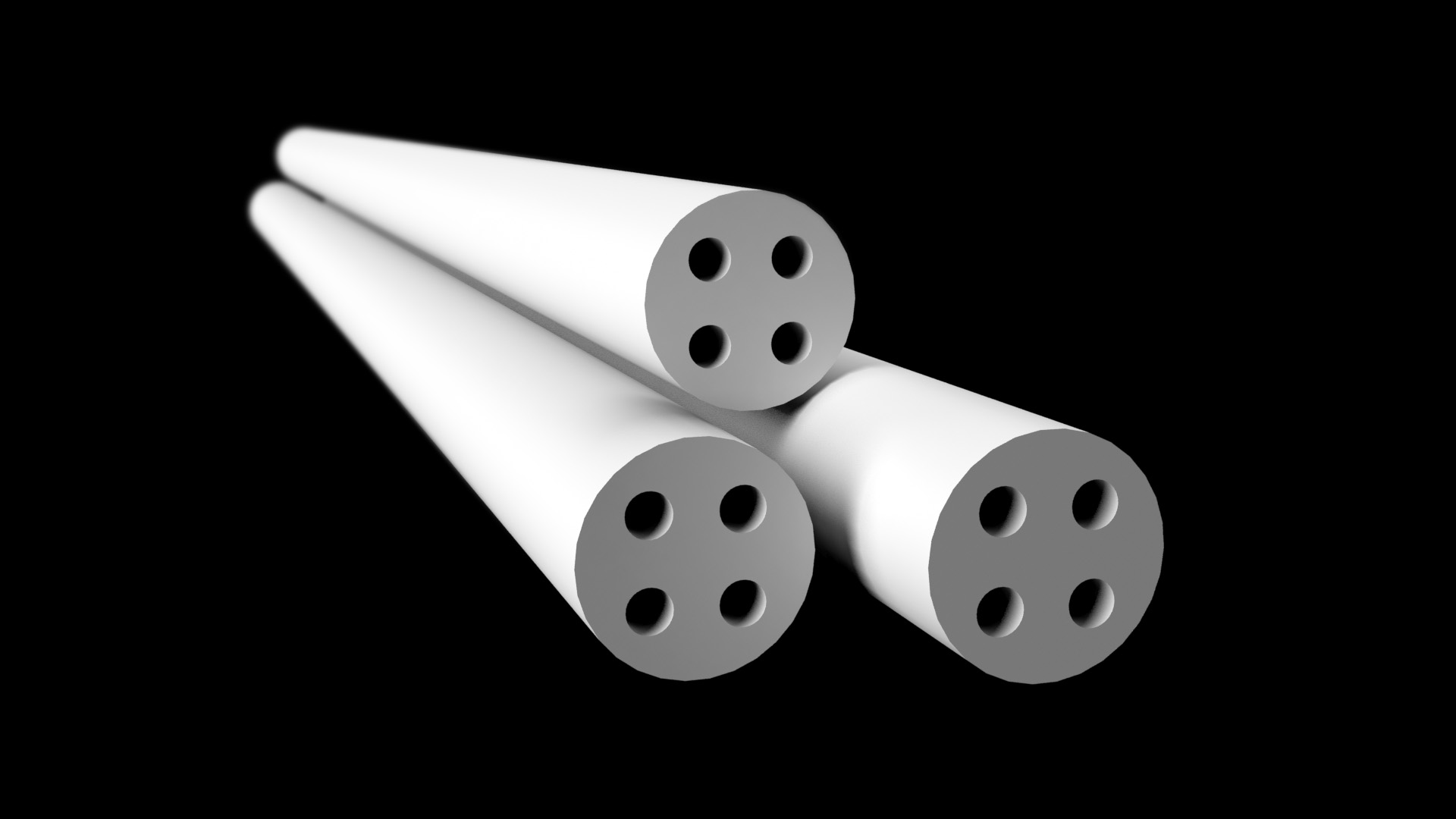

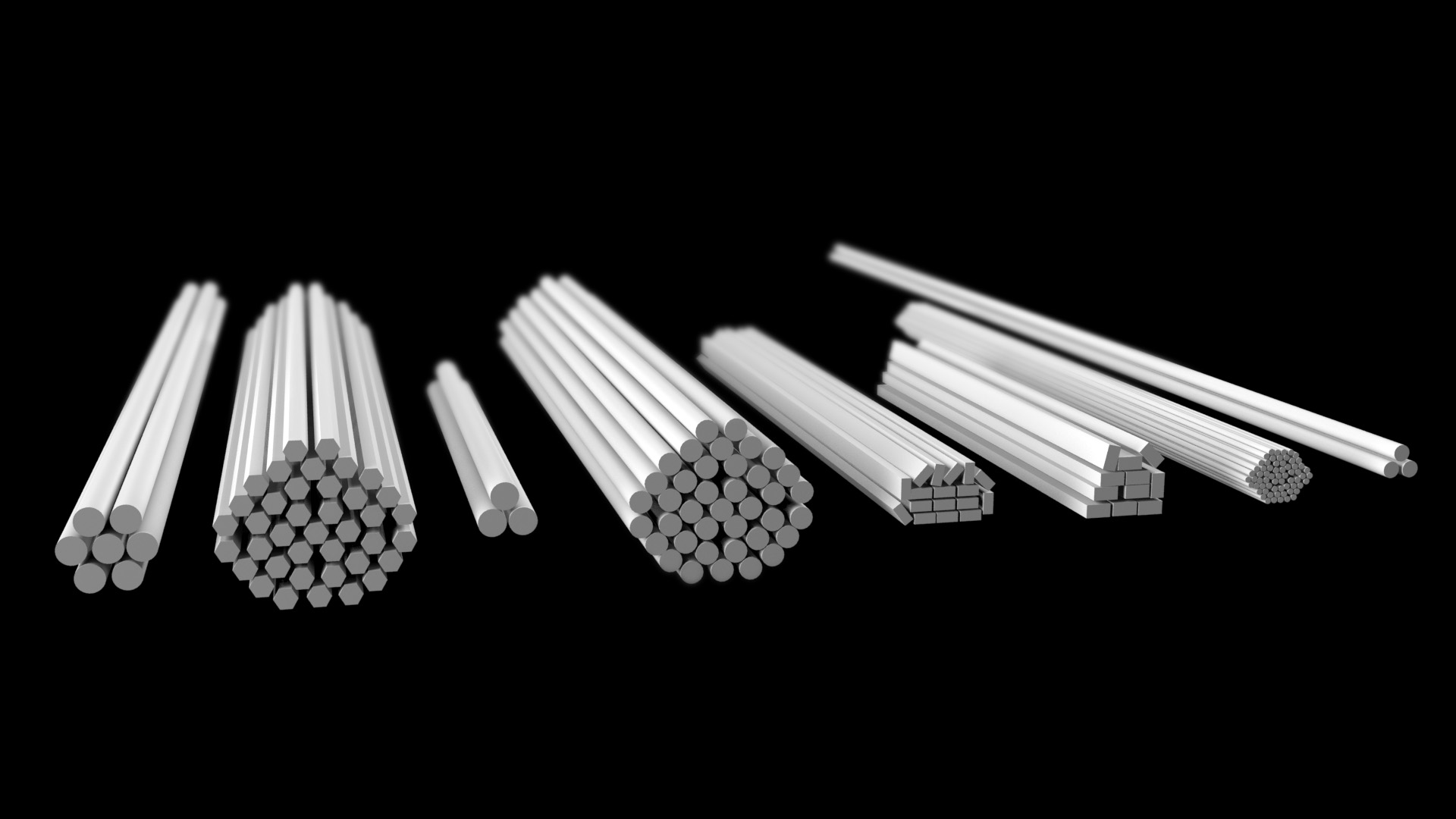

- Finished or semi-finished beryllium oxide profiles specially designed for electronic assemblies or as substrates for electronic circuits

- Products made of oxide-beryllium composite (BeO + TiO2) ceramics